What Is Traditional WPC Decking?

Traditional WPC decking is made from wood fibers and plastic (usually recycled polyethylene ). The mixture is extruded into boards that mimic the look of real wood while offering better resistance to rot, insects, and weathering.

Pros of Traditional WPC Decking

- Cost-Effective – Generally cheaper than co-extruded composite decking .

- Eco-Friendly – Uses recycled materials.

- Low Maintenance – Doesn’t require staining or sealing like wood.

- Good Durability – More resistant to cracking and splintering than natural wood.

Cons of Traditional WPC Decking

- Prone to Moisture Absorption – Can swell or warp over time.

- Fading & Staining – UV exposure and spills can affect color.

- Surface Scratches – More susceptible to wear compared to capped WPC decking .

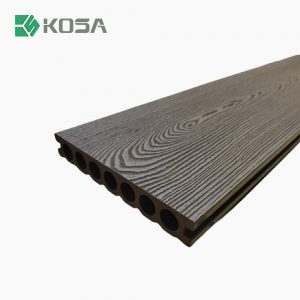

What Is Co-Extruded WPC Decking?

Co-extruded WPC decking (also called Capped Decking or Co-Extrusion Composite Decking) features a dual-layer construction :

– Core Layer : A standard WPC blend for structural strength.

– Protective Shell : A high-density polymer coating that shields against moisture, UV rays, and scratches.

This advanced manufacturing process enhances performance and longevity.

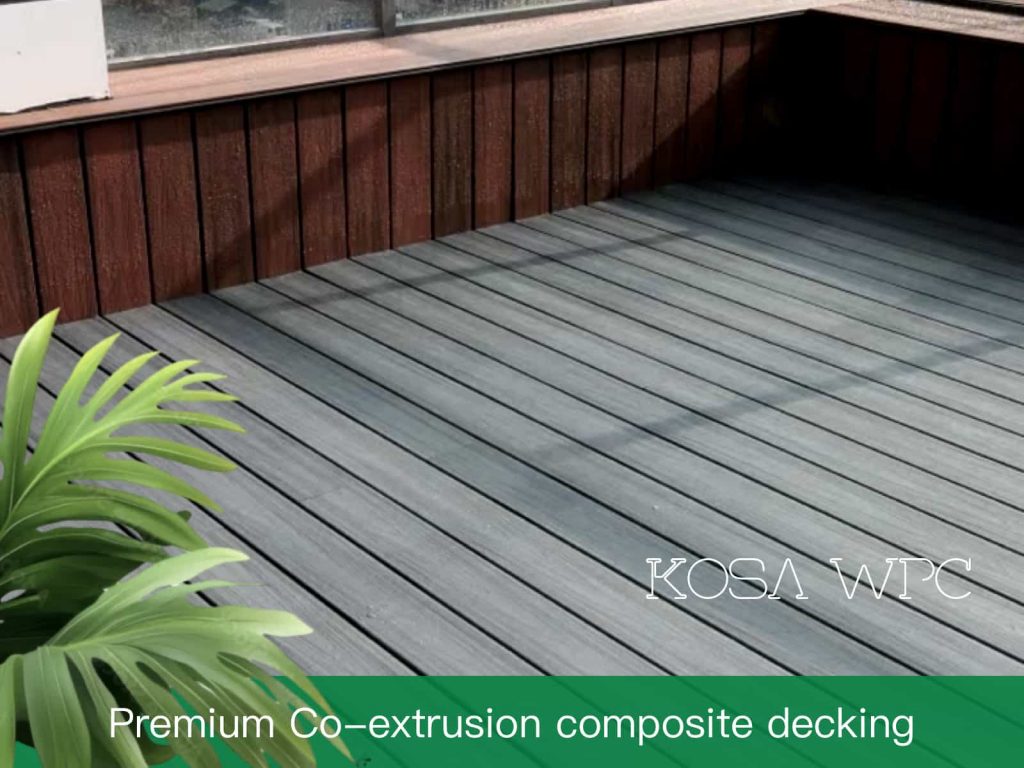

Pros of Co-Extruded WPC Decking

- Superior Moisture Resistance – The outer layer prevents water absorption, reducing warping and mold growth.

- Enhanced UV Protection – Resists fading and discoloration longer than traditional composite decking .

- Increased Durability – More scratch-resistant and better at handling heavy foot traffic.

- Easier Cleaning – The smooth, non-porous surface repels stains and dirt.

- Longer Lifespan – Typically lasts 25+ years with minimal maintenance.

Cons of Co-Extruded WPC Decking

- Higher Cost – More expensive upfront due to advanced manufacturing.

- Limited Color Options – Fewer natural wood-like finishes compared to uncapped WPC decking .

Key Differences: Co-Extruded vs. Traditional WPC Decking

Key Differences: Co-Extruded vs. Traditional WPC Decking

| Feature | Traditional WPC Decking | Co-Extruded WPC Decking (Capped Composite Decking) |

| Moisture Resistance | Moderate (can absorb water) | Excellent (protective shell prevents absorption) |

| UV Resistance | Good, but may fade over time | Superior, retains color longer |

| Scratch Resistance | Moderate | High (harder surface) |

| Maintenance | Low, but may need occasional cleaning | Very low, easy to clean |

| Lifespan | 15-20 years | 25+ years |

| Cost | More affordable | Higher initial cost |

| Aesthetic Options | More wood-like textures & colors | Limited due to polymer coating |

Which One Should You Choose?

Choose Traditional WPC Decking If:

✔ You want a budget-friendly decking solution .

✔ You prefer a wider variety of wood-look finishes .

✔ Your deck area has moderate weather exposure .

Choose Co-Extruded WPC Decking (Capped Composite Decking) If:

✔ You prioritize long-term durability and weather resistance .

✔ Your deck is exposed to heavy rain, humidity, or intense sunlight .

✔ You want minimal maintenance and maximum scratch resistance .

Final Verdict

While traditional WPC decking is a solid choice for budget-conscious buyers, co-extruded composite decking (capped WPC decking) offers superior protection against moisture, UV damage, and wear. If you’re looking for a deck that lasts decades with little upkeep, the higher initial investment in co-extrusion WPC decking is worth it.

For high-traffic areas, coastal climates, or commercial applications , co-extruded WPC decking is the clear winner . However, if cost is a major concern and you’re okay with periodic maintenance, traditional uncapped WPC decking remains a reliable option.

FAQs

- Does co-extruded WPC decking look like real wood?

Yes, but it may have fewer grain patterns compared to traditional composite decking .

- Can co-extruded WPC decking be painted or stained?

No, the protective polymer cap prevents staining or painting.

- Which type is more slip-resistant?

Both offer slip resistance, but textured capped composite decking may perform slightly better when wet.

- Is co-extruded WPC decking eco-friendly?

Yes, it still uses recycled materials, but the additional polymer layer may make it slightly less biodegradable than standard WPC decking .

- How do I maintain co-extruded WPC decking?

Simply wash with soap and water—no sealing or sanding required.

Conclusion

Both traditional and co-extruded WPC decking have their advantages. Your choice depends on budget, climate, and desired maintenance level. For long-term performance and weather resistance, co-extruded composite decking (capped WPC decking) is the best investment .

If you are looking for premium decking solutions, explore our range of high-quality WPC decking options , including Co-extrusion WPC decking, 3D embossed WPC decking traditional composite boards today!