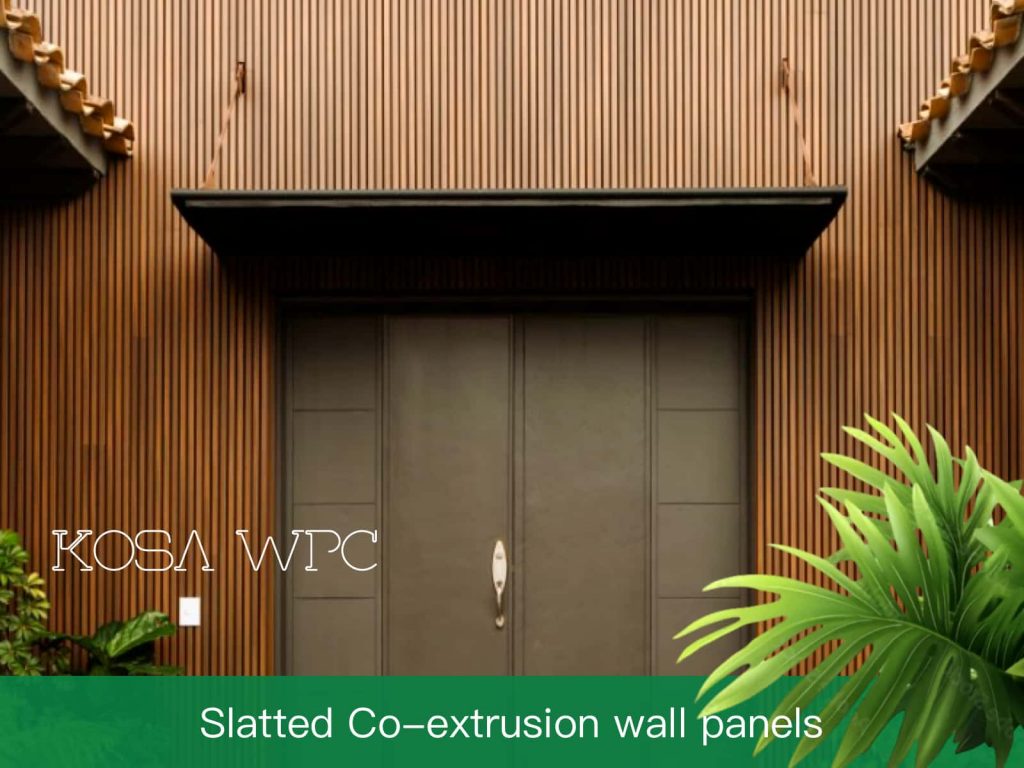

Wood-Plastic Composite (WPC) wall panels are a smart and eco-friendly choice for modern buildings. They are widely used in both indoor and outdoor spaces—from home interiors to commercial facades—thanks to their durability, low maintenance, and natural wood-like look.

But not all WPC panels are the same. There are two main types on the market:

1st Generation WPC panels – basic design, standard performance

2nd Generation co-extruded WPC panels – upgraded with better protection, longer lifespan, and improved appearance

In this article, we’ll break down the main differences, show real-world applications, and guide you on how to choose the best WPC wall panel for your next construction or renovation project—whether you’re designing a home, office, hotel, or retail space.

1. Material Structure and Manufacturing Process

1st Generation WPC Wall Panels:

The 1st generation WPC wall panels are made from a simple blend of wood fiber, plastic, and chemical additives. The entire panel is a single, homogenous material created through a standard extrusion process.

Example: A homeowner installing traditional WPC wall panels for a garden fence might notice mild color fading after a few months due to UV exposure.

2nd Generation Co-extruded WPC Wall Panels:

The 2nd generation Co-extruded panels feature a core-and-cap structure. The core is similar to 1st Gen WPC, but it is covered with a high-performance, weather-resistant polymer shell using co-extrusion technology.

Example: A commercial building uses co-extruded panels for an exterior facade, and even after years of rain and sun exposure, the surface retains its vibrant color and smooth finish.

2. Durability and Weather Resistance

1st Generation WPC panels:

More prone to surface scratching, fading, and water absorption over time.

Limited protection from UV rays, mold, and staining.

2nd Generation Co-extrusion WPC panels:

Enhanced resistance to weather, moisture, and color fading.

The outer shell protects against scratches, mold, and stains, making it ideal for harsh climates.

Example: In coastal areas with salty air and heavy rain, co-extruded panels remain unaffected, whereas 1st Gen panels may warp or discolor.

3. Aesthetic Appeal and Color Retention

1st Generation WPC cladding:

Limited color options and prone to uneven fading.

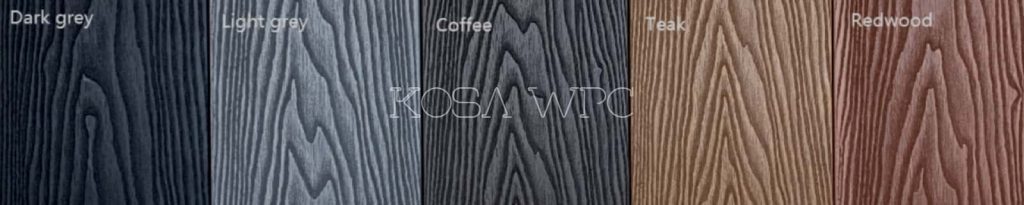

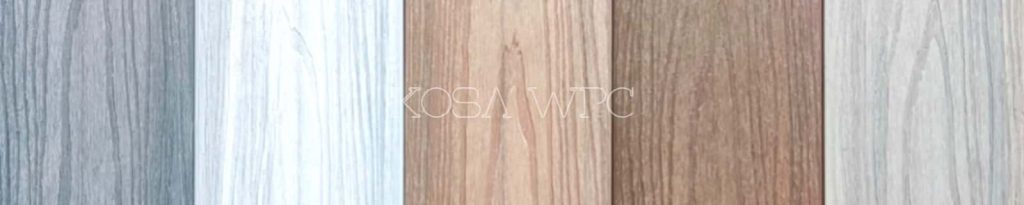

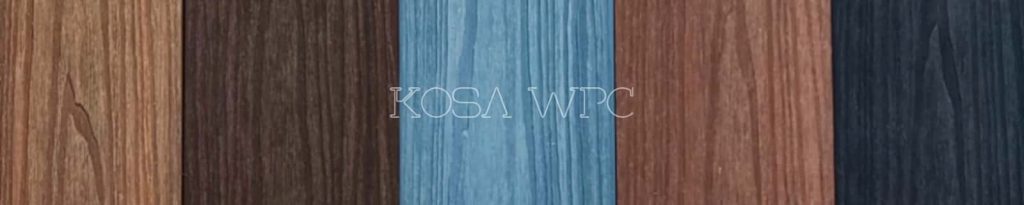

2nd Generation Co-extruded WPC cladding:

Available in a wide variety of colors, grains, and finishes that closely mimic natural wood.

Superior UV resistance means the color stays consistent over time.

Example: A designer selecting panels for a luxury resort prefers co-extruded WPC for its rich, long-lasting woodgrain textures.

4. Maintenance and Lifespan

1st Generation WPC wall panels:

Requires occasional sealing or treatment to maintain appearance.

Shorter lifespan under harsh environmental conditions.

2nd Generation Co-extruded WPC wall panels:

Virtually maintenance-free—no painting, sealing, or staining required.

Can last 25+ years with minimal upkeep.

Example: A public facility manager chooses co-extruded WPC for a park pavilion to reduce long-term maintenance costs.

5. Cost vs. Value

1st Generation WPC wall cladding:

Lower initial cost, but may incur higher long-term maintenance and replacement expenses.

2nd Generation Co-extruded WPC wall cladding:

Slightly higher upfront investment, but superior performance and durability offer better long-term value.

Example: A homeowner opts for co-extruded panels after comparing lifecycle costs and realizing they’ll save on repairs and repainting over 15–20 years.

Conclusion: Which One Should You Choose?

If the budget is limited, or the project is short-term and low-demand, the 1st generation WPC wall panels can meet basic needs. But if you pursue long-term durability, maintenance-free, and high-value effects, the 2nd generation co-extruded WPC wall panels are definitely a wiser choice!

Whether you are an owner, designer, builder or contractor, choosing the right wall panel material can make the project more worry-free, more valuable, and more beautiful! “